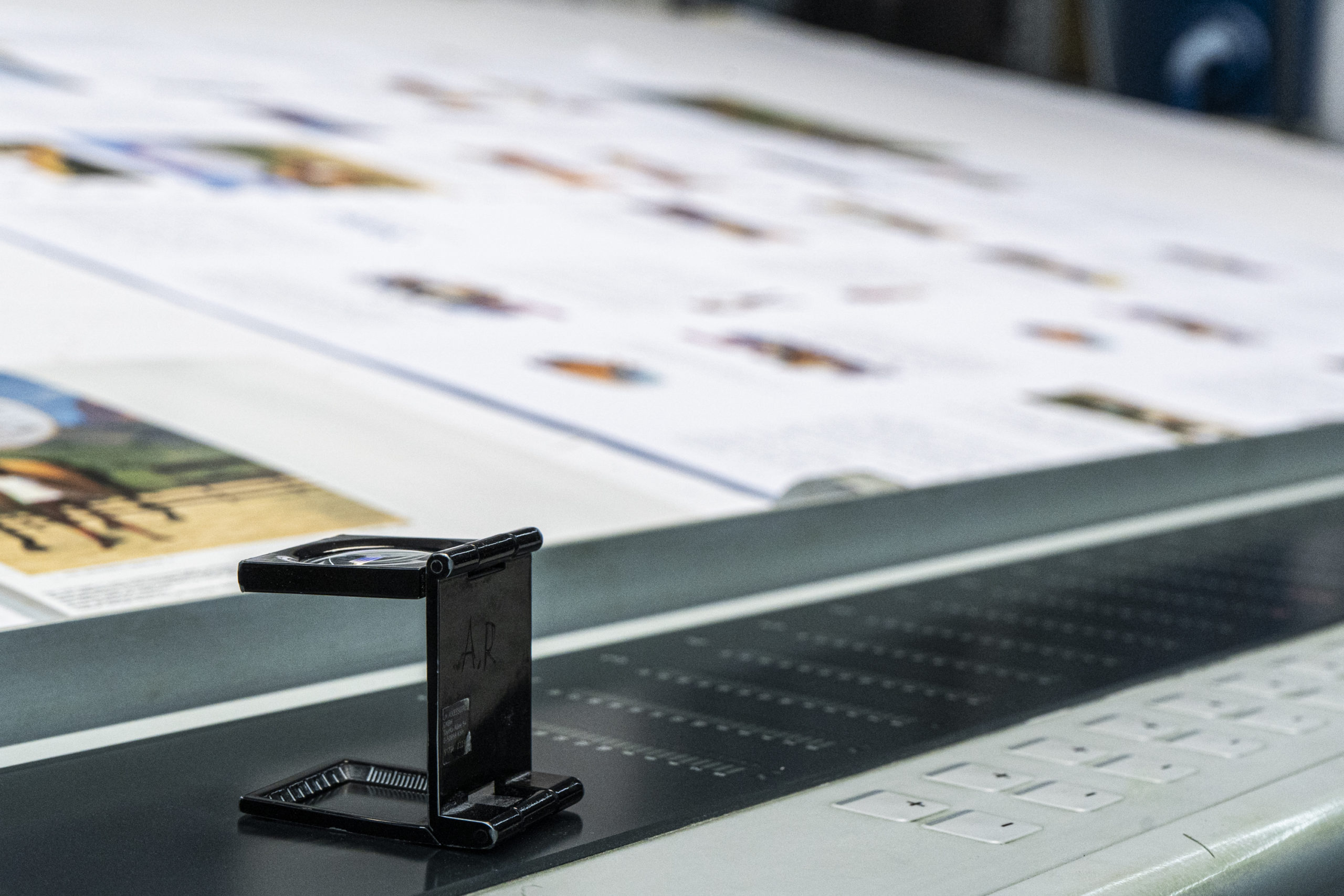

The most modern sheet-fed printing equipment in the Iberian Peninsula.

In order to offer a fully integrated and specialized service to our clients, Macrolibros has all the necessary equipment in-house

We have the most modern and up-to-date large format printing and binding equipment in the Iberian Peninsula.

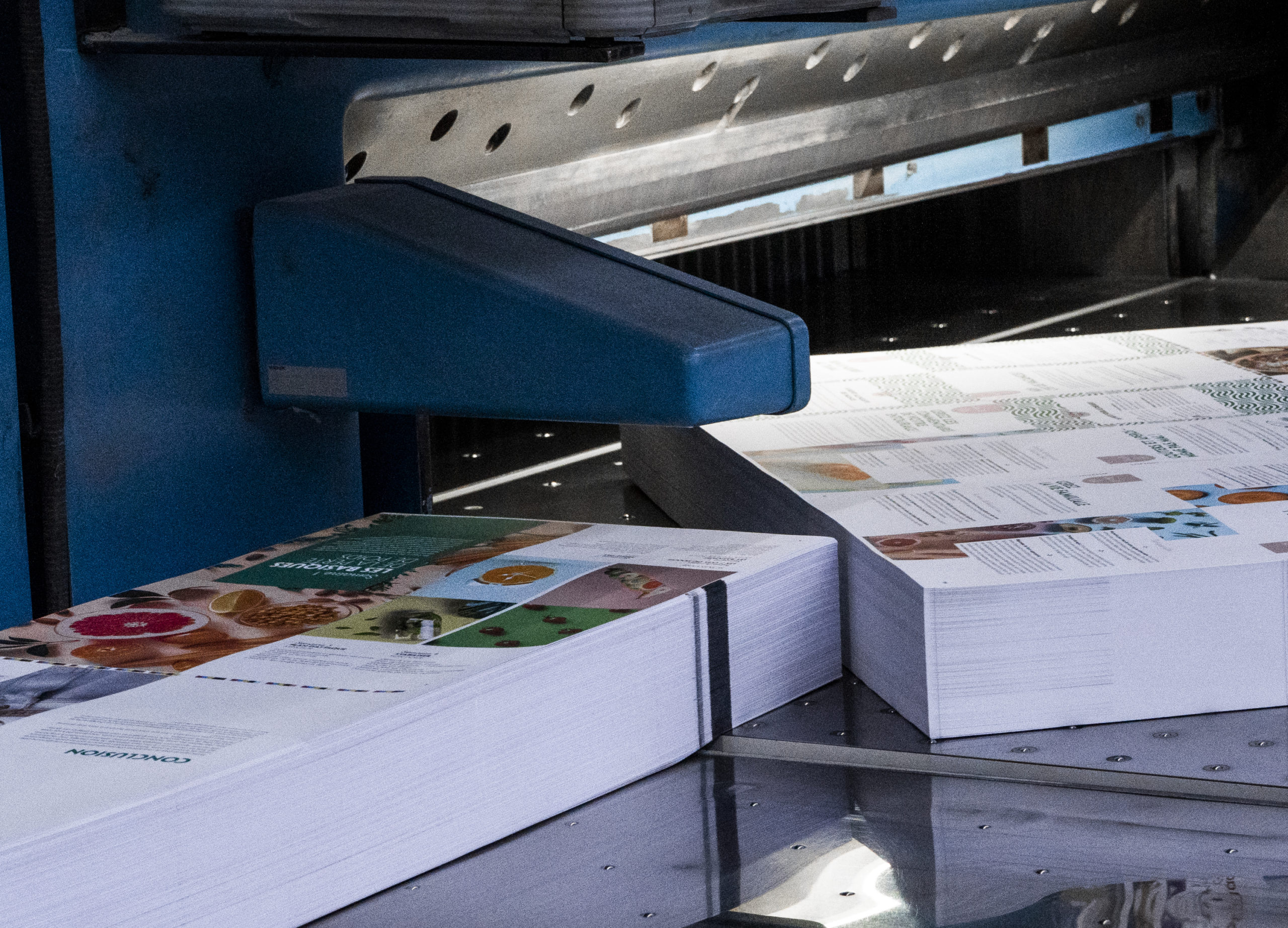

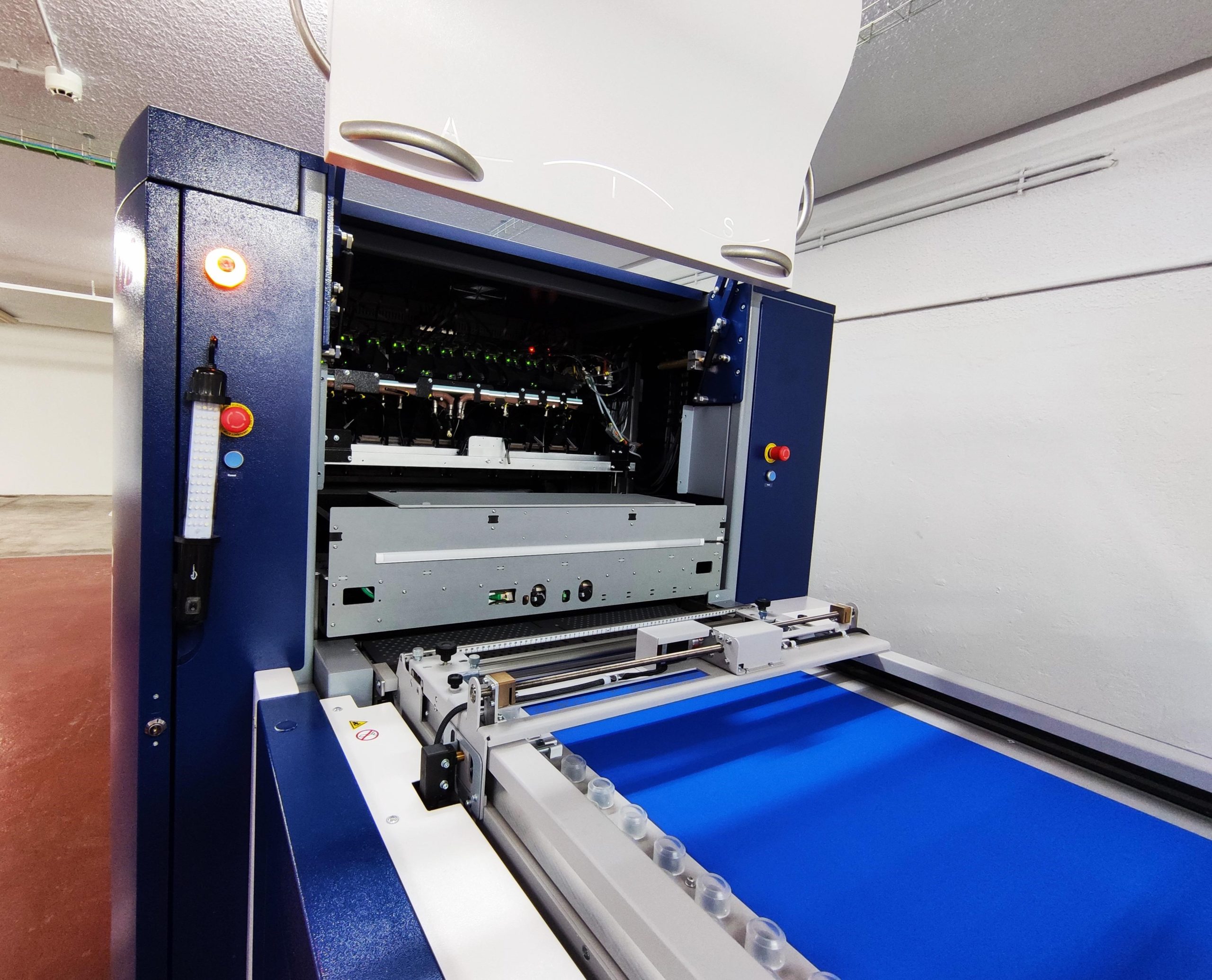

In order to be able to offer a better service, quality and reduced production time, and to allow our clients to diversify their cover finishing needs at a very competitive price and without increasing the production time, Macrolibros has added to our traditional equipment the first finishing line in Spain that can produce in-line spot UV varnishes (in both 2D or 3D), textured varnishes and foil stampings on a sheet size of 75 x 120 cms.

- Equipped with an automatic register control cell.

- “Artificial Intelligence Smart Scanner” which automatically corrects any register deviation. The above finishes will register perfectly with the offset printing throughout the whole run.

- The machine can produce different varnish thicknesses, from 3 to 280 microns, and different foil stamping colors, in the same pass.

- The same printed sheet that passes through our film lamination equipment enters the finishing line.

- Variable data with spot UV or foil stamping? In Macrolibros it is possible!

- No extra freight costs nor added production time since all the processes are done in house. Better control, security and quality as well as fastest production turnarounds.

In order to be able to offer a better service, quality and reduced production time, and to allow our clients to diversify their cover finishing needs at a very competitive price and without increasing the production time, Macrolibros has added to our traditional equipment the first finishing line in Spain that can produce in-line spot UV varnishes (in both 2D or 3D), textured varnishes and foil stampings on a sheet size of 75 x 120 cms.

- Equipped with an automatic register control cell.

- “Artificial Intelligence Smart Scanner” which automatically corrects any register deviation. The above finishes will register perfectly with the offset printing throughout the whole run.

- The machine can produce different varnish thicknesses, from 3 to 280 microns, and different foil stamping colors, in the same pass.

- The same printed sheet that passes through our film lamination equipment enters the finishing line.

- Variable data with spot UV or foil stamping? In Macrolibros it is possible!

- No extra freight costs nor added production time since all the processes are done in house. Better control, security and quality as well as fastest production turnarounds.

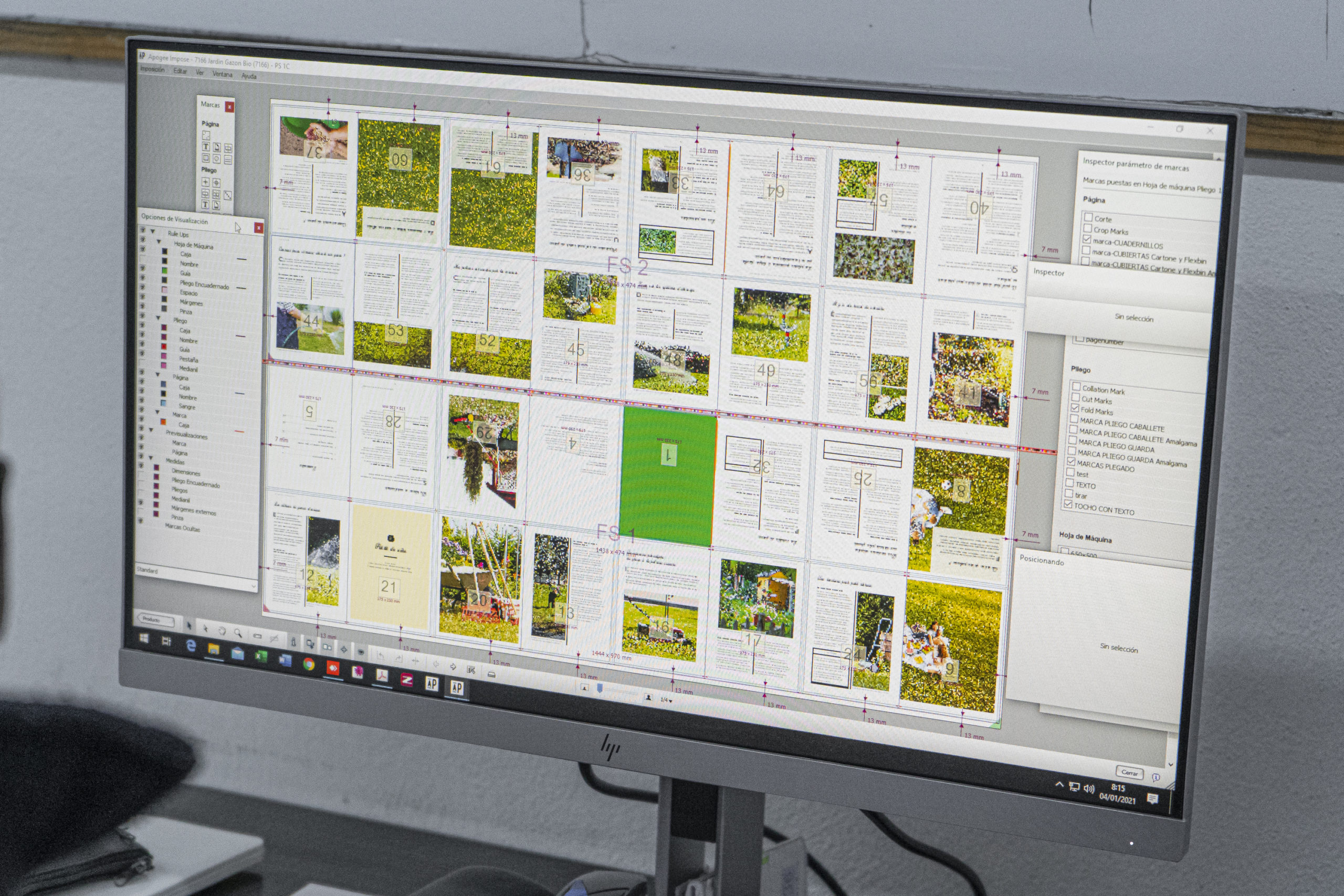

Printing:

- 3 presses in size 1200 x 1600 mm.: one with 4 colors, one with 5 colors and one with 8 colors “perfector 4+4”.

- 1 press in size 740 x 1060 mms. with 5 colors for covers, endpapers and jackets

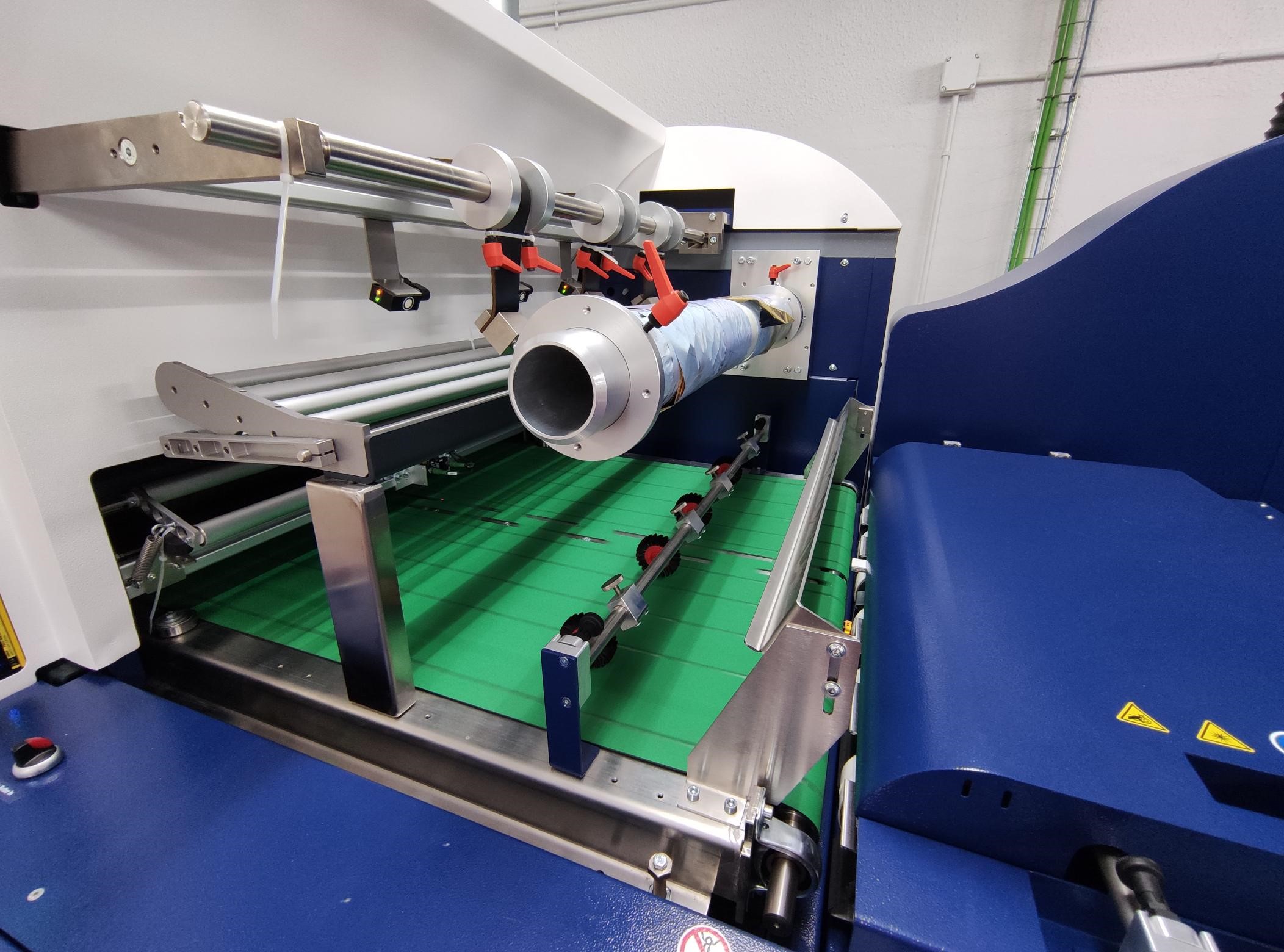

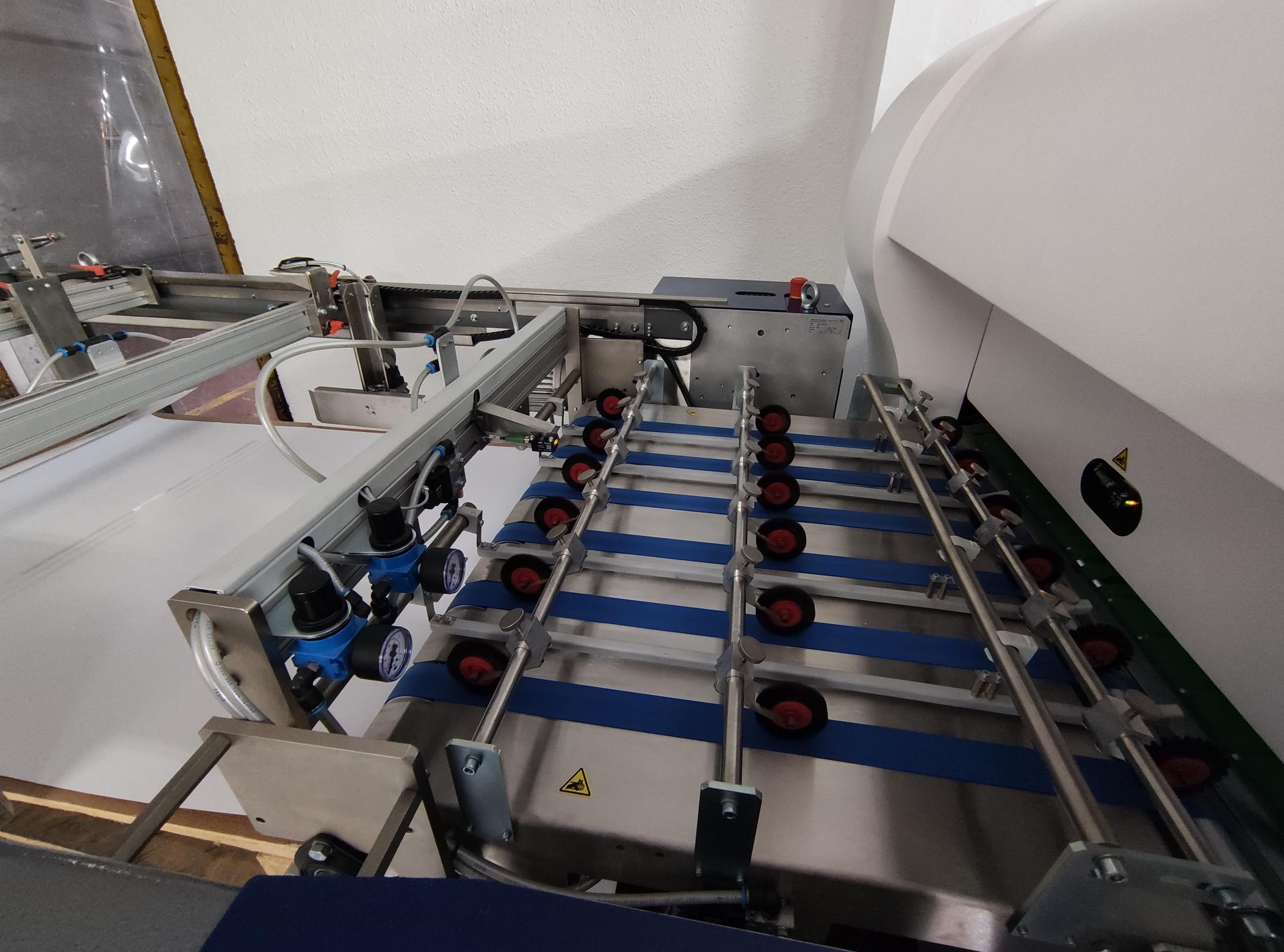

- 1 film lamination line with DRY technology that allows us to finish the covers in-house without having to outsource the lamination.

- 1 Jet Varnish finishing line to apply UV spot varnishes, textured varnishes and foil stamping.

Printing:

- 3 presses in size 1200 x 1600 mm.: one with 4 colors, one with 5 colors and one with 8 colors “perfector 4+4”.

- 1 press in size 740 x 1060 mms. with 5 colors for covers, endpapers and jackets.

- 1 film lamination line with DRY technology that allows us to finish the covers in-house without having to outsource the lamination.

- 1 Jet Varnish finishing line to apply UV spot varnishes, textured varnishes and foil stamping.

Jet Varnish + Hot Foil

The best solution for your book, magazine, catalogue, label, card or box. In short, the best solution for your printed product, printed and bound in Macrolibros. A product designed for digital printing adapted to the offset technology to cover small or large runs without production problems nor outrageous costs.

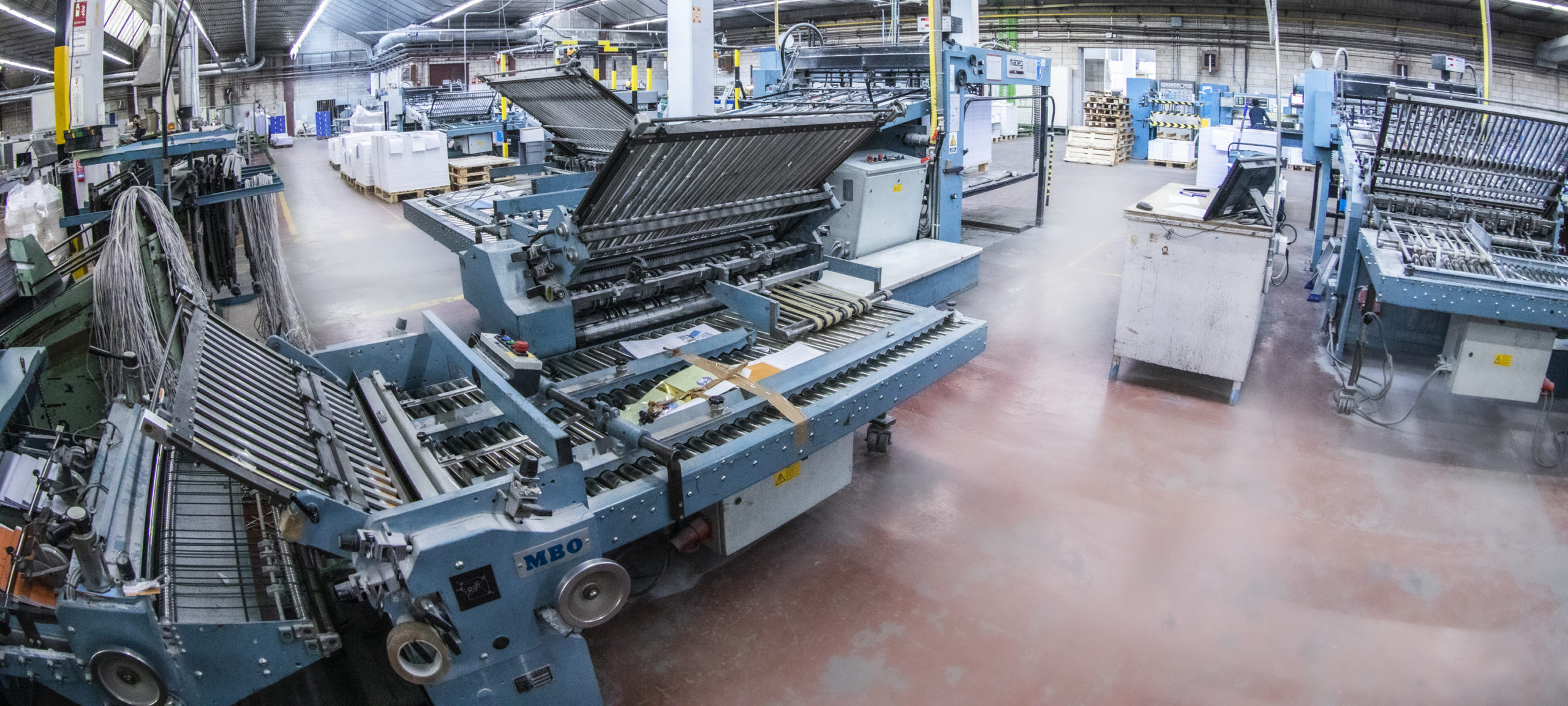

Binding:

- 5 large size folding machines

- 2 small size folding machines

- 2 thread sewing lines with 15 pockets

- 2 thread sewing units (with on-line assembly and sewing)

- 2 hard cover case making machines

- 1 foil stamping machine to stamp finished cases

- 1 flexibound cover making machine

- 1 machine to fold flaps for softcover books

- 1 wire stitching line with 5 pockets + cover unit

- 1 softcover binding line (with or without sewing and with or without flaps)

- 2 hardcover/flexibound binding lines

Binding:

- 5 large size folding machines

- 2 small size folding machines

- 2 thread sewing lines with 15 pockets

- 2 thread sewing units (with on-line assembly and sewing)

- 2 hard cover case making machines

- 1 foil stamping machine to stamp finished cases

- 1 flexibound cover making machine

- 1 machine to fold flaps for softcover books

- 1 wire stitching line with 5 pockets + cover unit

- 1 softcover binding line (with or without sewing and with or without flaps)

- 2 hardcover/flexibound binding lines